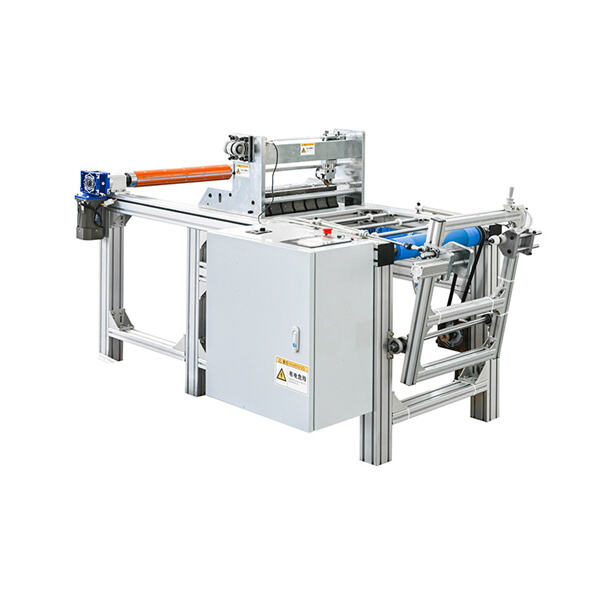

Welcome to YL, is a privately owned enterprise operating in microfiber warp and weft knitted terry cloth, warp and weft knitted coral velvet, pigtail cloth, small chenille, polyester, nylon sticky button cloth and finished products.

Contact Info

-

Email

[email protected] -

Phone

+86-13814922607 -

Address

No.92 Jinghua Avenue, Xiyuan Town, Zhangpin, Longyan City, Fujian, China